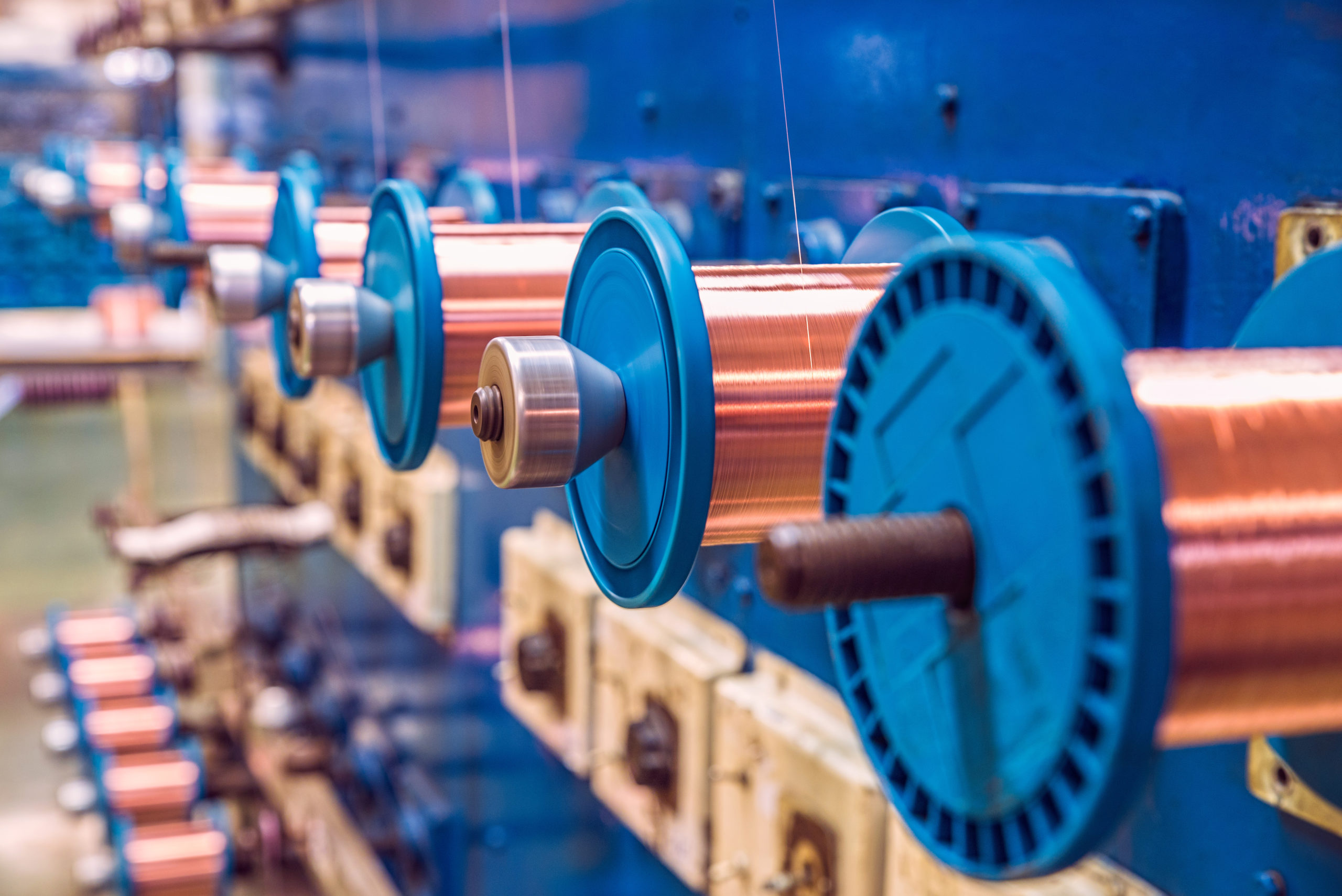

Copper, aluminum and alloys are the most commonly drawn metals, particularly in the cables manufacturing.

The parameters of the dies must take into account the material drawn, the final diameter, the coating and the characteristics of your machine, especially if it is a multiwire.

Multiwire drawing

Wire drawing on multiwire machines requires reliable, accurate dies with the right geometries to protect you against the risk of wire breakage.

Thanks to its know-how and a perfectly mastered manufacturing process, Balloffet is your best partner for the supply of drawing dies for all types of metals, including coated, even in the smallest diameters.

Multiwire – Copper

Multiwire – Fine wires

Multiwire – Aluminum

Copper wire drawing on multi-wire machines

Given the number of dies involved and the precision required, you need to be competitive:

- To reduce the risks of wire breakages

- Tight tolerances to avoid metal overconsumption

- Dies sequences in perfect fit with the machine parameters

- To reach optimal drawing speeds

- To increase the dies lifespan

To meet these requirements, Balloffet dies secure:

- Accurate and well-respected geometries for each die

- An excellent polishing

- Tightened diameter and ovality tolerances

- Adapted profile to your materials (alloys, coated wires, tinned copper…)

- Elongation control

- Personalized Marking

Fine wire drawing on multiwire machines

The growing need for small-sized wireline solutions that save natural resources, energy, weight and space, are at the heart of the concerns of many industrial sectors: automotive, energy, transport, etc…

Balloffet is the specialist for fine wire drawing on multiwire machine, down to Ø 0.050 mm.

Our manufacturing processes and our services secure you with:

- Identical geometries for all the dies

- Tightened tolerances (0.5 µm for Ø – 0.4 µm for ovality)

- Selection and crystallographic orientation of the natural diamond enforced by our experts.

- Die elongation control

- Dies sequences Repolishing based on the same quality standards than the ones of new dies

- Personalized Marking

Aluminum drawing on multiwire drawing machines

Aluminium flexible cables market is growing, particularly in the automotive or aeronautics industry, but there are some issues :

- Aluminium is a sticky material, which rises the pulling in the dies, and therefore wire breakages risks.

- Creation of ships during the drawing, which contaminates the lubricant and makes dies wearing faster.

- Take profit of drawing dies which will help you to reach optimal operational speed of your most modern machines.

BALLOFFET is firmly established in the field of aluminium drawers on multiwire machines and has implemented solutions adapted to aluminum types or alloys, wire diameter and the to your machine’s characteristics.

- Mixt sequences between single and polycrystalline

- Case by case studied geometry

- Individualised finish (extra-polish – angles blending …)

- Help for dies sequences calculation, elongations and slip.

Liaise with us to benefit from our advices.

Rod-break down machines (Rod)

Primary drawing machines, whether mono or dual wire, are increasingly technically advanced.

They allow you to reach speeds close to the multiwire.

To make the most of them, the choice of the dies is essential to obtain the best return on investment.

The use of Balloffet dies guarantees:

- The choice of the best PCD blanks: Excellent quality/productivity

- The most suitable geometries to the material drawn and your machine characteristics (speed, elongation, lubrication …)

- A lengthened repolishing interval

- A dies maintenance service in the conditions of new dies

- An efficient analysis and maintenance dies maintenance service

Wires and bars drawing

Balloffet dies guarantee the best quality of wire drawn on single or dual-wire machines, with the best return on investment :

- Choice of single or polycrystalline diamond type

- Natural diamond crystal selection and orientation by our experts

- Mirror-polished diamond surface

- Individualised geometry

- Tightened tolerances to optimize your raw material consumption

For copper, aluminium, brass, steel bar drawers … The use of diamonds allows to gain in productivity and competitiveness (diameter precision/ Optimization of the consumption of raw material).

The Balloffet dies guarantee an optimal lifespan :

- Reinforced special mounting

- Individualised geometry based on drawing characteristics

- Diamond mirror-polished surface

- Finish and casing to meet your requirements

- New repolising with or without diameter change

Alloys, Copper or Aluminum Drawing

Depending on the user industries, many types of copper or aluminum alloys are drawn.

The wire deformation conditions vary mainly according to their hardness and chemical composition.

Balloffet offers you dedicated dies to the drawing of:

- Brass

- Tinned copper

- Copper magnesium

- Tin copper

- Bronze

- Alumoclad

- Almelec

- Berylium

- …