Industrial sectors and applications

The growing needs for increasingly small “wired” solutions, saving natural resources, energy, weight and footprint, are at the heart of the concerns for a large number of fields such as electronics (semi-conductors, supra-conductors…), medical, transport, environment, chemical, etc.

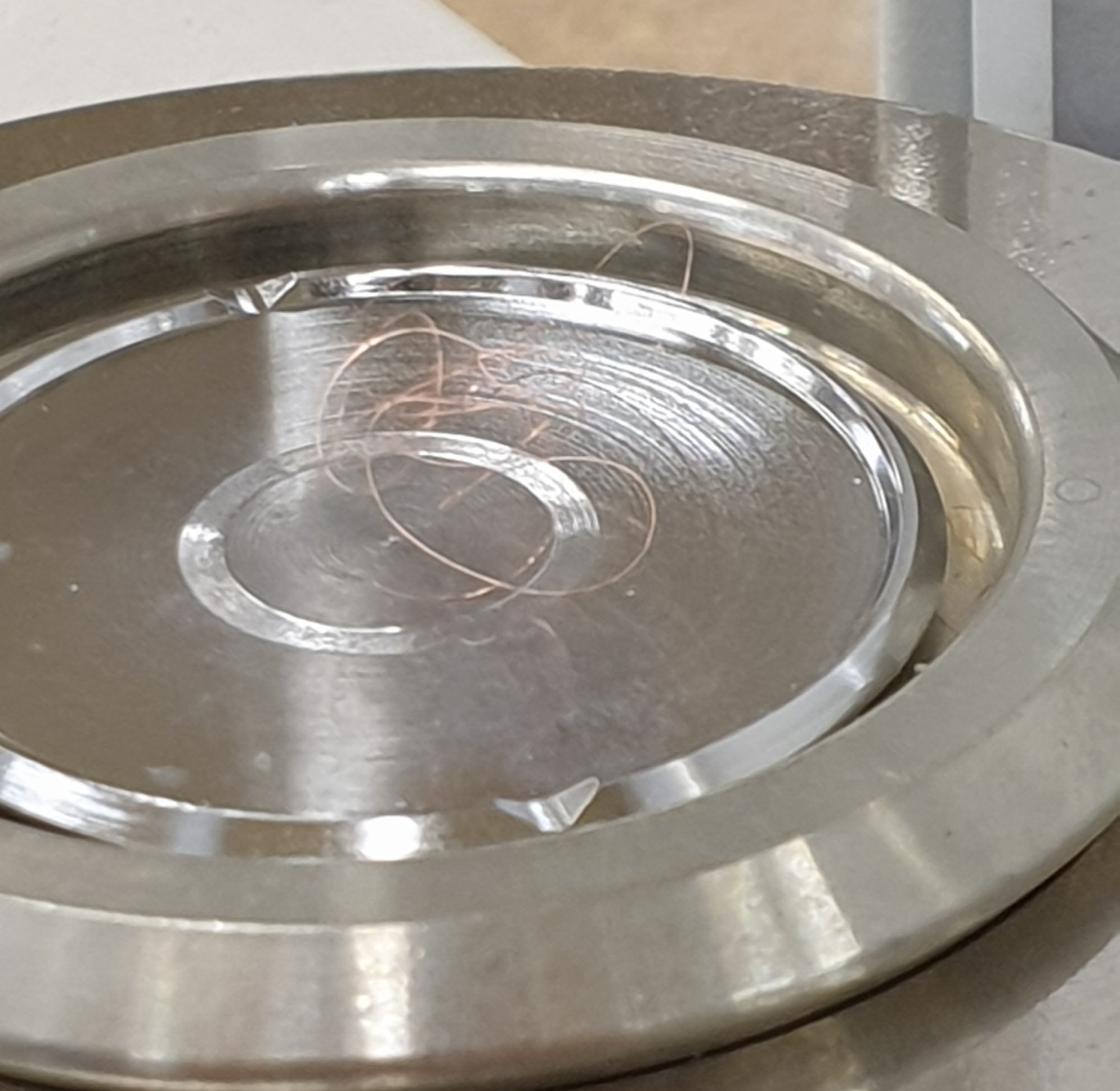

Balloffet offers a fully integrated global expertise in the design and manufacturing of fine (thin) and ultra-fine diamond dies (as small as Ø 6.5 µmm) with tight tolerances.

For your round and shaped fine wires, based on our know-how, our dedicated and experienced team advises and supports you in the implementation of wire drawing solutions for many metals and applications.

Manufacturing Process

- Feasibility study, assistance and follow-up or your request: metal to be drawn, type/shape section (wire or tube pipe), tolerances…

- Diamond type selection: monocrystalline diamond (SSCD) or natural (ND)

- Die manufacturing in accordance with the agreed specifications

- Wire control: optical, volumetric weight, tolerance, elongation control of dies sequences, calibration/ adjustment on wire sample reference (if necessary).

The complete mastery (100%) of our methods and processes provides a very high-quality level:

- Reliability and reproducibility of our adjustment and polishing techniques thanks to dedicated and experienced specialised operators

- Ultra-high vertical and horizontal Balloffet rotation machines use (> 6000 rpm) to respect diameter and roundness tolerances

- Top diamond surface finish quality

- High straightness and wire aspect

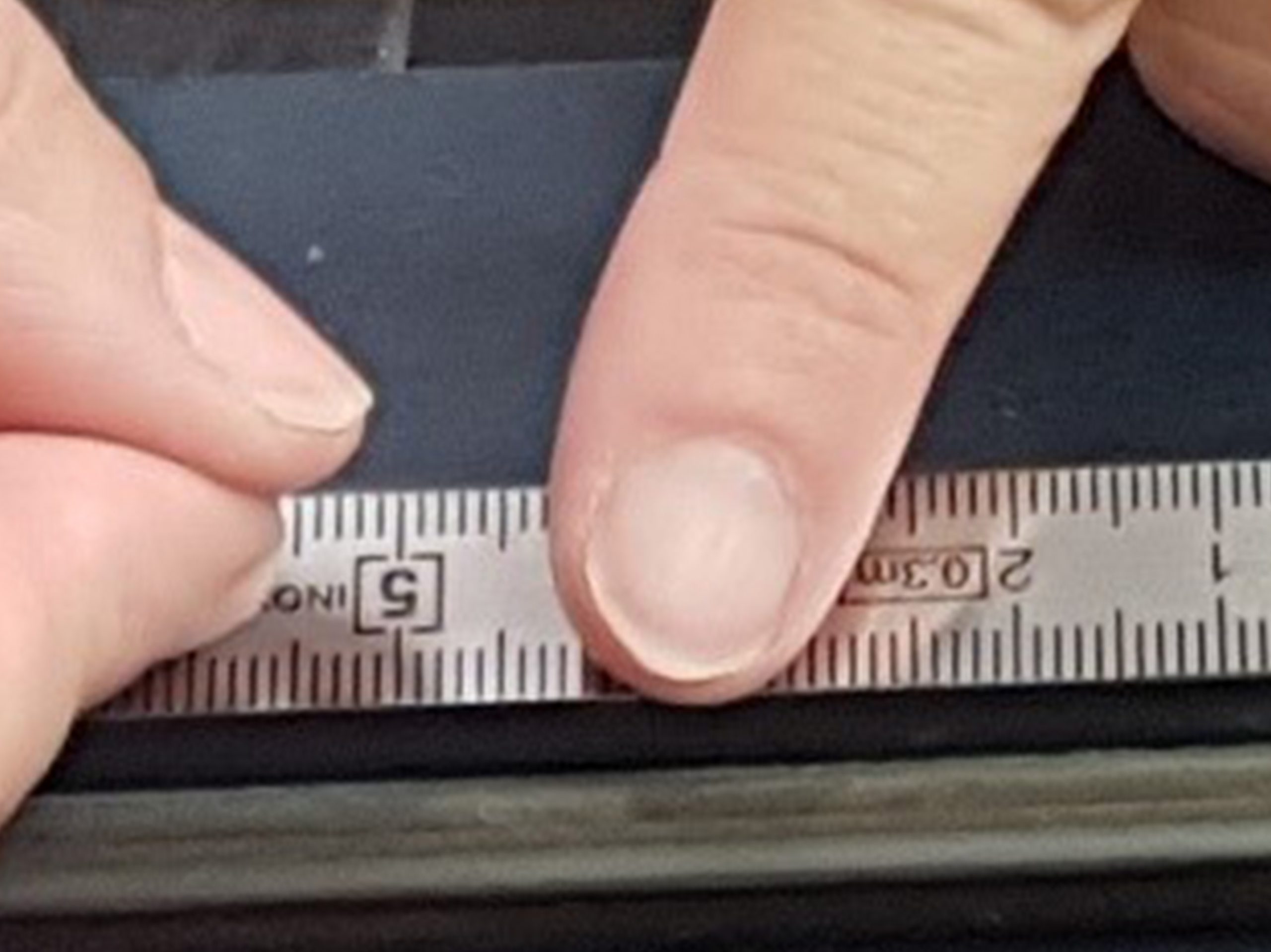

The diametre and tolerance are controlled by wire weight. This technique is the most accurate. Elongation controls or touch free controls (laser) are also possible, depending on your request.

- 6 to 25µ : +/- 0.1µ

- 25 to 35µ : +/- 0.15µ

- 35 to 50µ : +/- 0.20µ

The ovality

- 6 to 25µ : +/- 0.15µ

- 25 to 35µ : +/- 0.2µ

- 35 to 50µ : +/- 0.25µ

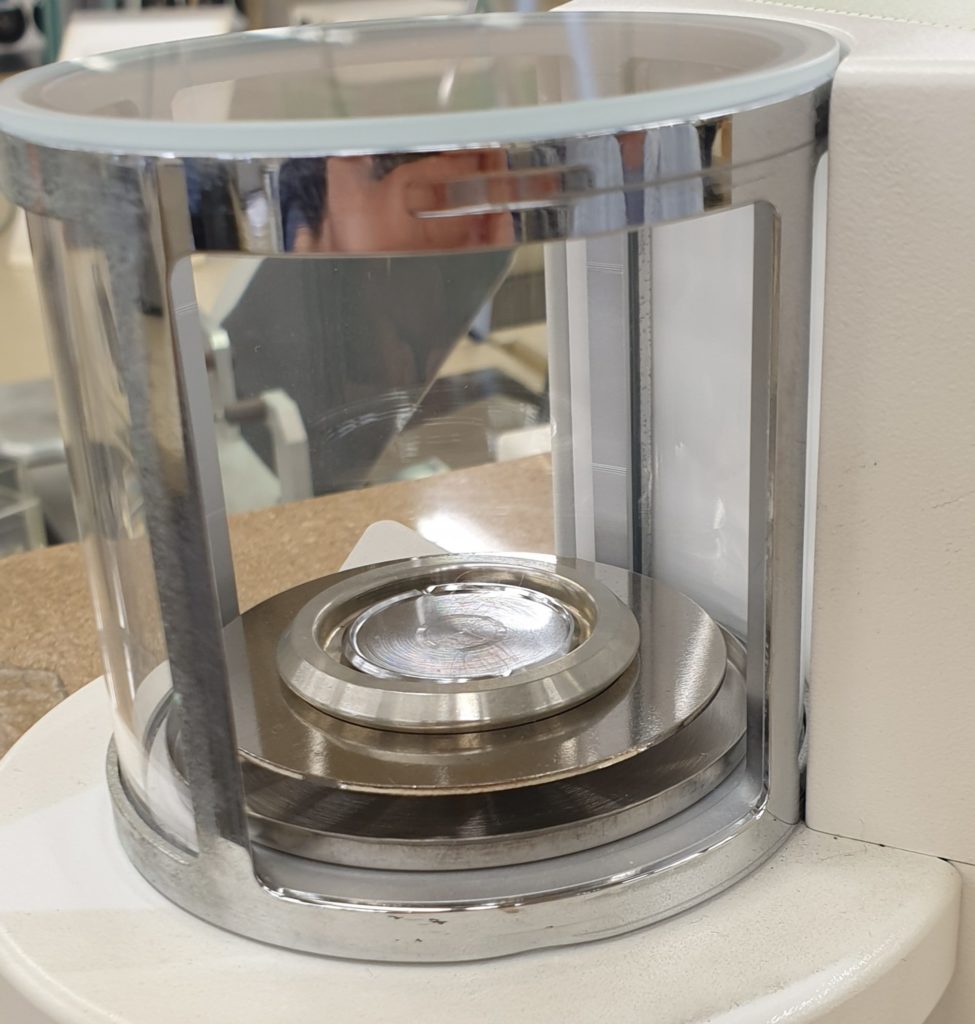

Control Method

After wire pulling in the die produced, several equipments and devices are available to achieve the controls:

Dimensional

- Touch free control

- Weight measurement control (volumetric mass)

- Elongation control

Complementary

- Control with large magnification (diamond finish of the dies)

- Optical control of the wire (diamond finish, wire geometry…)

You are welcome to liaise with us for any project.

Dedicated ultra-fine dies division

Tolerances down to 0.2µ