Dies Maintenance and Recut

For an optimal productivity and Return on Investment of your dies, the refurbishing or recutting must be operated extremely carefully.

A regular maintenance of your diamond dies reduces the overall drawing costs thanks to the restoration of the initial dies’ performances, which are similar to new ones with BALLOFFET.

A quality service for dies like new

The refurbishing of your dies follows the same process used for new dies.

- Diamond dies: PCD, SSCD, ND

- Diamond dies repolishing or recutting based on wear level

- Identical tolerances to new dies

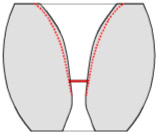

- Reshaping of the angles and bearing

- Geometry profile change possible

- Casing change optional

- Repolishing of any brand

Process

Analysis

Each die is individually analysed to determine the wear level and consequently, the work to be done:

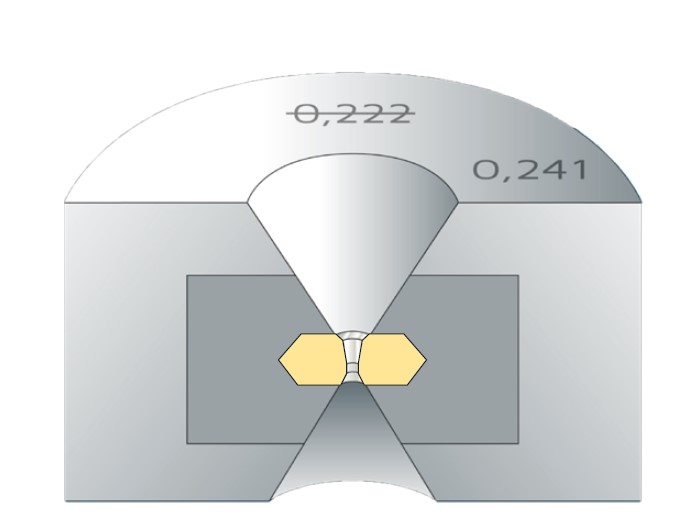

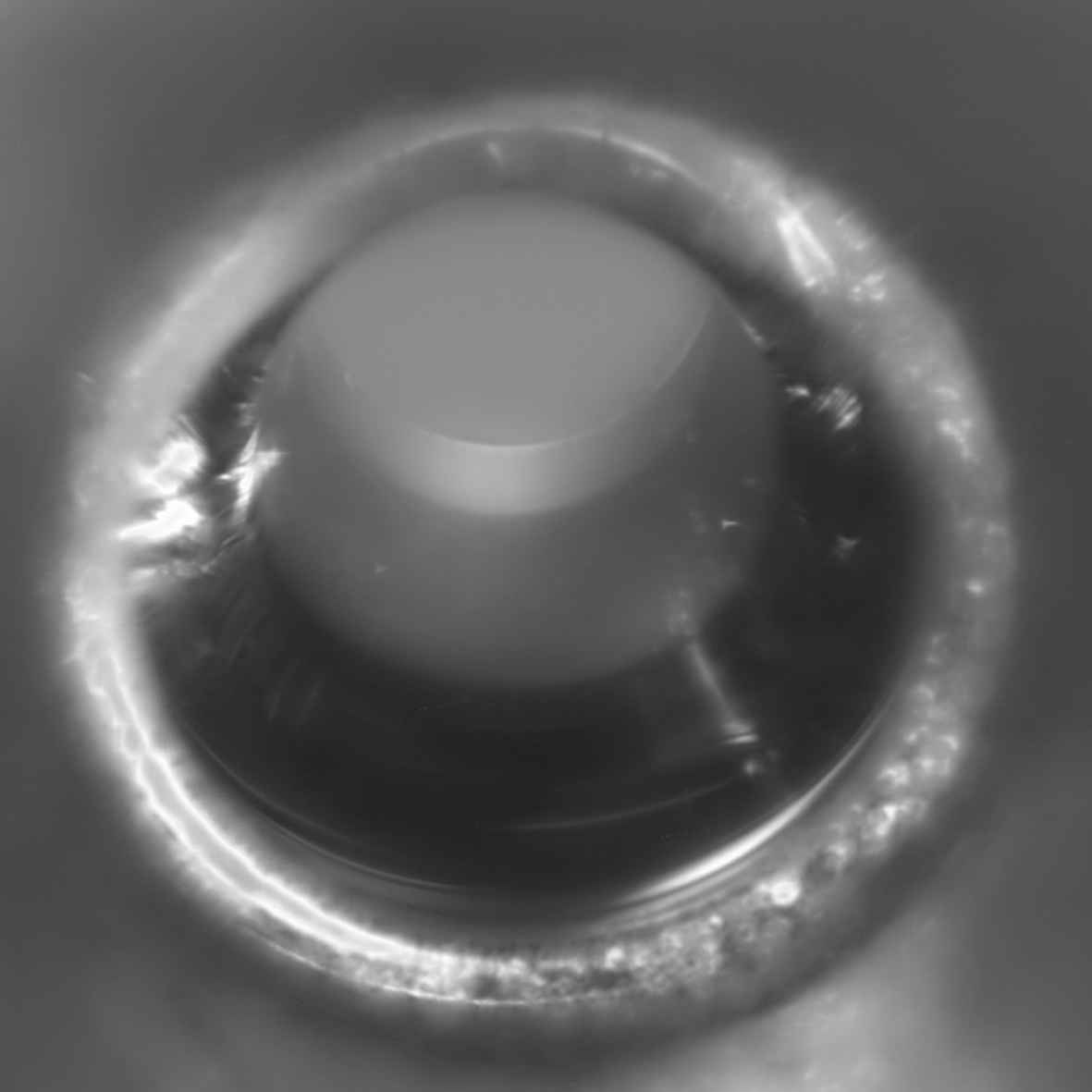

SLIGHT WEAR:

Polishing of the die at the same diameter.

Small opening of the reduction angle.

Example : PCD die

NORMAL WEAR:

Complete recutting of the die’s shape with reworked angles and diameter change.

Example : DN die

Depending on the work required (polishing or recutting), the dies enter the production circuit of new dies at the cut, angles shaping or bearing polishing level.

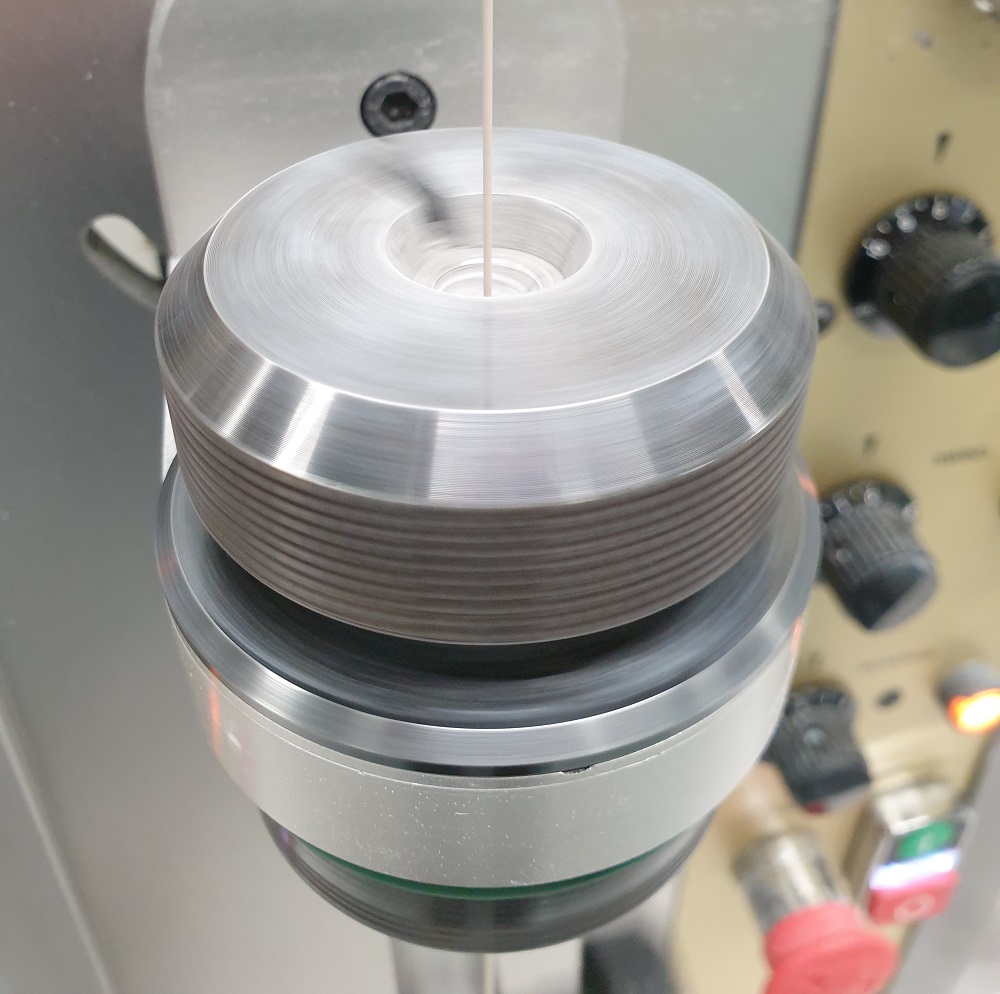

Elongation control of the dies sequence(s)

For small diameters (< 0,20mm) part of dies sequences, we can control your dies by measuring the elongation, based upon your machine kinematics.

Each die belonging to the sequence is identified and marked for a quick implementation on your machine.

Analysis advice

The dies are individually analysed. We get in touch with you if there is an abnormal wear or any concern.

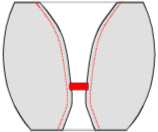

- visual examination (wear level, surface condition, wire drawing ring…)

- dimensional geometric examination

- diamond examination (X-Ray)

- assistance to the detection of a possible issue (lubrication, shocks, raw material, vibrations, elongations, slip…)

- recommendations

Emergency service « quick die shop »

3 Weeks as of date of order*

Our Quick-Die Shop secures your dies’ repolishing in 3 weeks.

Conditions :

- Less than 30 dies

- Diameters 0,10 to 3,00 mm

* transport time(s) excluded