The diameter control during the refurbishing process, as well as the final measurement, is usually made on a wire which has been drawn into a die.

The method has for major inconvenience to be time consuming for each control

It is essentially in order to reduce these measurement times, and to improve your productivity, that Balloffet has created its own VISIODIAM 3 equipment, also used in our workshop.

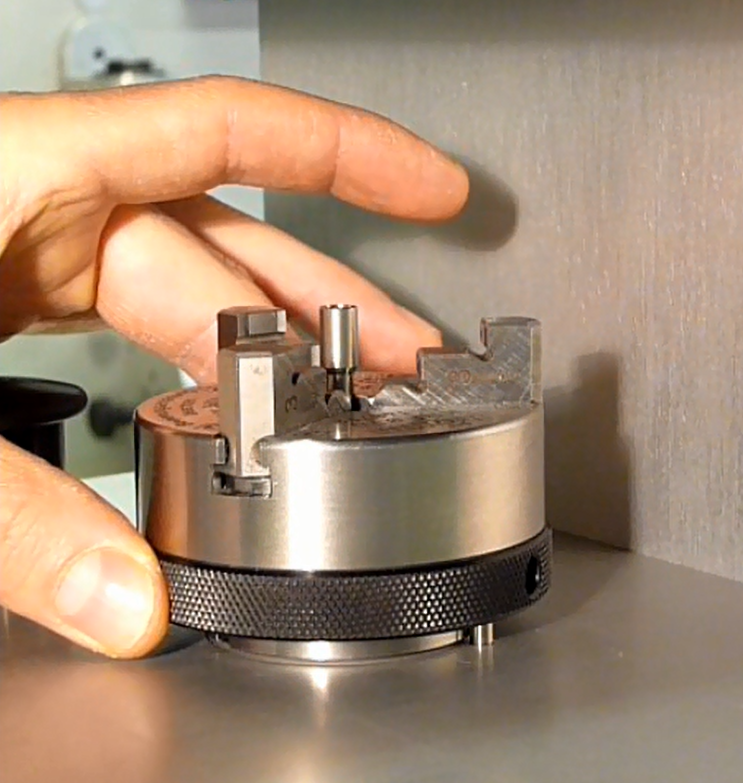

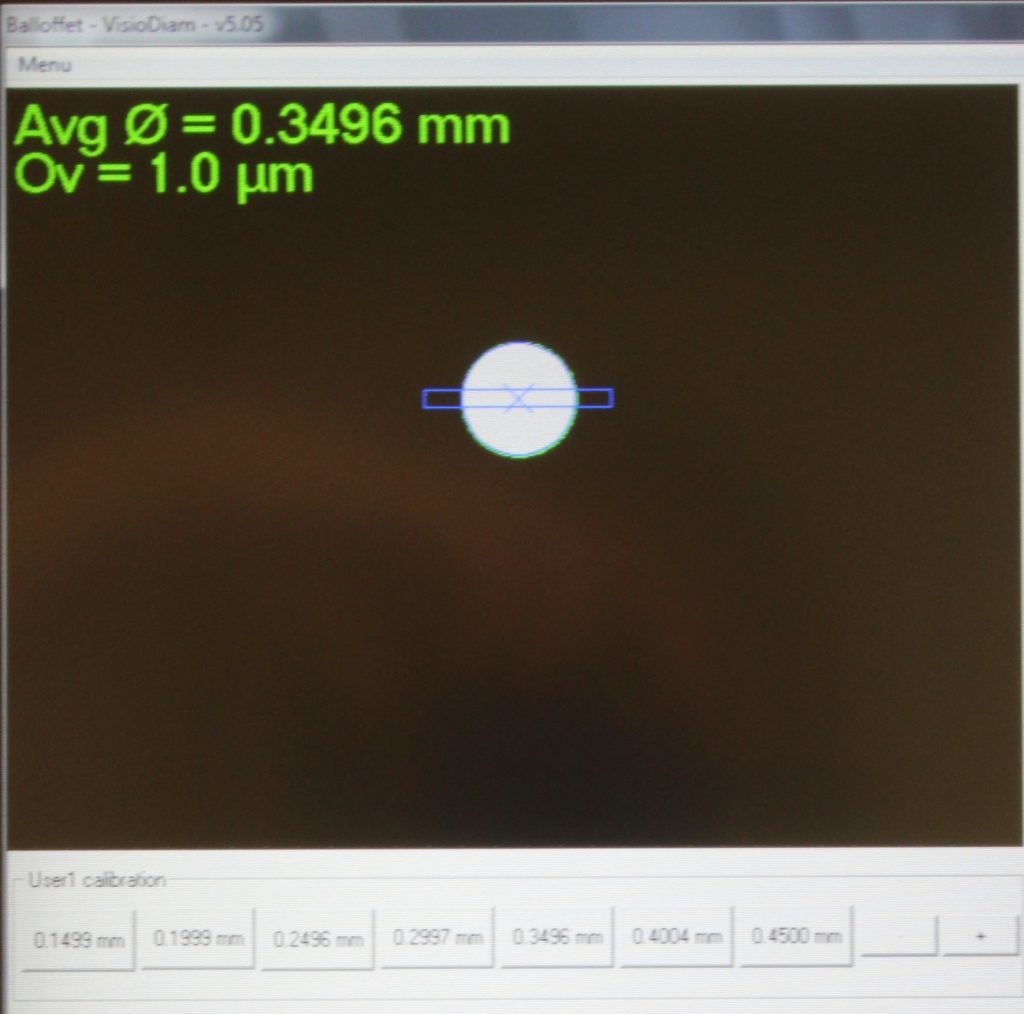

The VISIODIAM 3 allows you to check the diameter and roundness of your dies or enameling guides, in diamond as well as in tungsten carbide, by image analysis, without having to pull a wire inside the die

The measure is touchless, in a few seconds

- Range of standard diameters 10 – 2.50 mm – Other ranges available (max 9mm)

- Die diameter and roundness control

- Management of your drawing dies or enameling dies stock, in diamond as well as in tungsten carbide

- Quick and easy to use. Measure in less than 5 seconds

- 3 USB ports for data recording. Printer as an option

- Great return on investment

- Designed for an industrial use / Robust and reliable

- Supplied with master dies and digital pen

- Touchscreen 12“

Available Diameter Ranges

Play Video