For your cabling, stranding, bunching operations, BALLOFFET is offering you its DIAMCOATTM Nano dies, diamond coated.

Gathering the hardness and the advantages of the tungsten carbide, our DIAMCOATTM dies can be an alternative solution for the cabling, compacting, bunching or stranding of your copper, aluminum, or alloys cables.

Advantages:

- Wider diameter range than the PCD

- Die profile dedicated for stranding and/or compacting

- Life length from 5 to 10 times the one of the tungsten carbide

- Mirror polish surface finish

- Low friction level

- Diameter up to Ø80mm

- Shaped dies possible

- Very good ratio price/quality

- Unit production possible

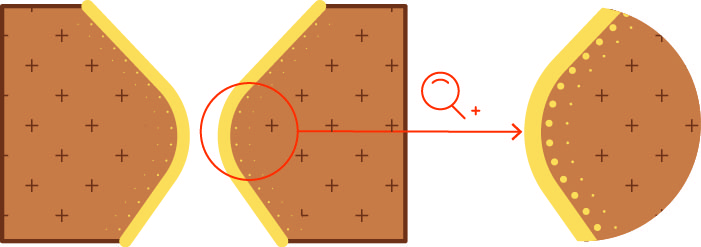

Technical details:

- Hardness around 10000Hv

- Tight tolerances

- High compaction rate

- Coating thickness 30 µm

- Tungsten carbide basis

- Very smooth angles blending => no risk of scratches or stripes on the cable

- Great finishing

Nano-Coated Drawing Dies DiamcoatTM for Low and High Carbon Steel – Welding Wire

The nano-coated dies DIAMCOATTM positively replace carbide dies for steels wire drawing. They are much more resistant to wear, thanks to the nano-diamond layer thickness and its mirror-polish surface finish. They allow to increase the wire drawing speeds, maximasing raw materials savings, for productivity gains.

Characteristics

- Nanocrystalline diamond coating

- Coating thickness 30µm

- In-depth coating penetration into the blank

- Tolérances Ø ± 5µm up to Ø 10 mm

Advantages

- Compatibles with any steel

- Diameter stability – Material savings

- Lifespan x15 mini / carbide

- Any type of lubrication