Forerunner in the conception of ultrasonics machines for the diamond drawing dies grinding, Balloffet is offering some high-performance equipment

Discover why is Balloffet the leader in the manufacturing of these machines

The ultrasound technology

Pioneer in the development of generators and ultrasonic heads for the machining of diamond dies, Balloffet remains the undisputed leader in the use of ultrasound to ensure the conical parts of the dies, an optimal geometry and a perfect finish.

The efficiency of the emission and transmission of ultrasound in Balloffet machines is due to the exclusive design by our engineers of the generator/amplifier/needle assembly which determines a longitudinal motion down to the active needle extremity in the die.

By meeting this challenge, Balloffet ultrasonic machines achieve unparalleled productivity.

- Generator power

- Precision and regularity in the dies’ angles machining

- Repetitive shapes of dies for multiwire series

- Reduced machining time in shaping and polishing

- Tens of thousands of ultrasonic movements per second

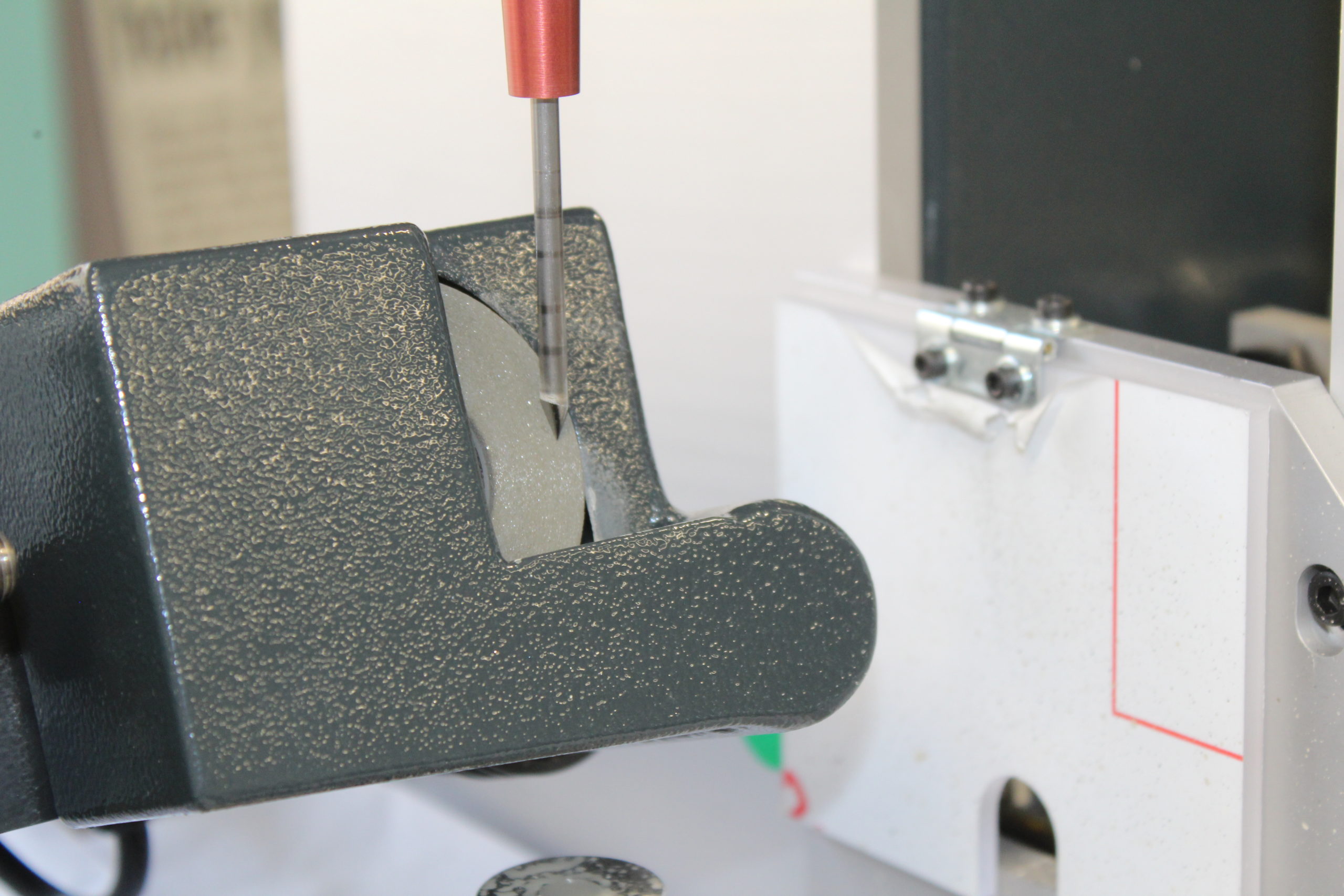

Exclusive needle insertion system

Balloffet has developed a unique system of needle attachment in the ultrasonics amplifier of its ultrasonics machines

This attachment by fitting needs neither a brazing nor a welding and grants an efficient transmission of the ultrasonics power, with a minimum loss between the ultrasonics generator and the top of the needle working into the die

50% more efficient than a classical system with needle brazed

- Less handling time

- Great alignment of the needle with the amplifier

- Self-centering of the needle into the die

- Increased productivity

- Safety for the worker

- Easy to use

Custom automation

Depending on the job to be done (shaping/polishing), on the quantities that have to be refurbished, and on your die-shop organization, the Balloffet machines are offering some automated and programmable modes

- Working cycles time

- Automatic cycles stop

- Die oscillation

- Ultrasonics power

- Regular needle sharpening

- Dies feed-in

- Dies evacuation

You still benefit from the most adapted machine regarding your needs, in order to bring you the best return on investment

Machines adapted to the refurbished diameters

Every single type of machine is dedicated to the diameters refurbished in your die-shop

They are mainly depending on the type of drawing machine and the nature of the material drawn

- Final drawing (Ø0.10 up to 3mm)

- Intermediate drawing (Ø0.10 up to 4mm)

- Rod drawing (Ø1.50 up to 9mm)

The power of the machine is adapted to each range of diameters

Needle PressTM

The Needle PressTM is the natural complement of Balloffet the ultrasonics machines, in order to benefit from the original attachment sytem

- Strong and easy attachment of the needle on the amplifier

- Perfect transmission of the ultrasonics power for an optimal efficiency

- Quick and easy use

- Great centering of the needle in the amplifier

Needle PressTM included with the BD 140 VGA evo2 machine

Durability

The ultrasonics machines are designed to combine productivity and durability

Hundreds of Balloffet machines are in use all over the world, some of them since more than 40 years

- Choice of the best mechanic, electric, electronic and pneumatic components

- Robust frames

- Regular, easy and quick maintenance

- Follow-up, maintenance or repair service in Balloffet or in your die-shop

These machines are used daily in our workshop for the manufacturing of our dies, known in the whole world for their quality and their yield

The Balloffet consumables

The use of the original Balloffet consumables is highly recommended to get the best yield and durability from our ultrasonics machines

Designer and manufacturer from A to Z