BALLOFFET is your best partner for the enamelled wire production, for its drawing and enamelling, to help you improve your competitiveness.

Make the most of your equipment regardless of your manufacturing process:

- Drawing then horizontal enamelling

- Drawing then vertical enamelling

- Drawing and enamelling on Tandem machine

Drawing Dies

The wire to be enamelled must comply with dimension accuracy and particular surface finish.

Balloffet dies guarantee :

- Tightened tolerances (down to 0.5 µm)

- The best wire surface finish for an excellent glaze grip

- Multiple possible for the Shaped enamelled wire

- The most suitable diamond choice

- A large diameter range from 6.5 µm

For your enamelled shaped wires too, Balloffet shaped dies guarantee you the best surface finish with a high dimensional accuracy.

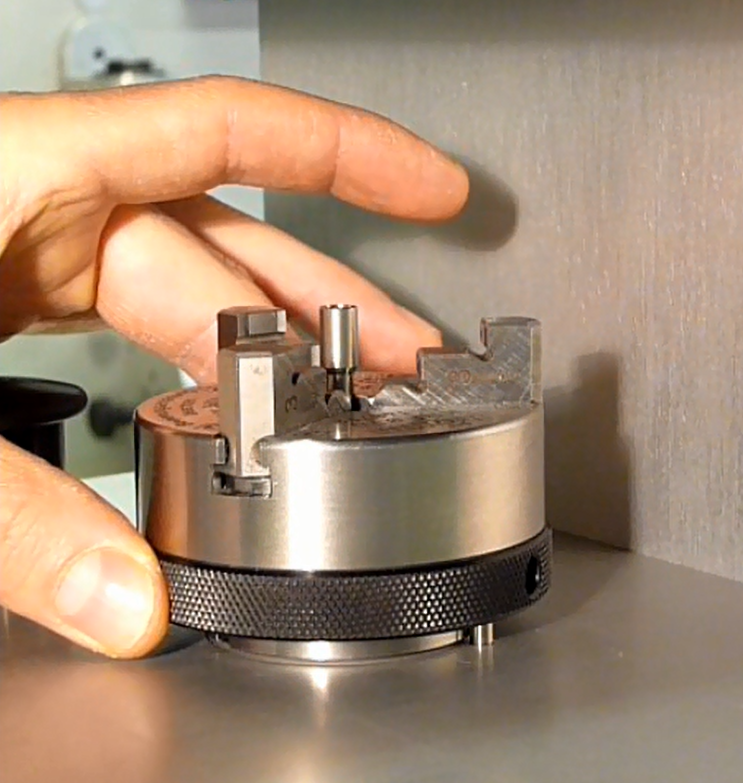

Enamelling Guides

The enamelling guides choice with diamond insert is the solution to improve your return on investment.

Benefiting from our expertise in diamond work, our enamelling diamond insert guides allow you to significantly improve your productivity:

- Spectacular reduction of maintenance times

- Glaze consumption reduction

- Maintaining layers of enamel over time

- Suitable for horizontal, vertical, tandem machines

- 100 times longer life than carbide guides

- No change to your machine or guide frames

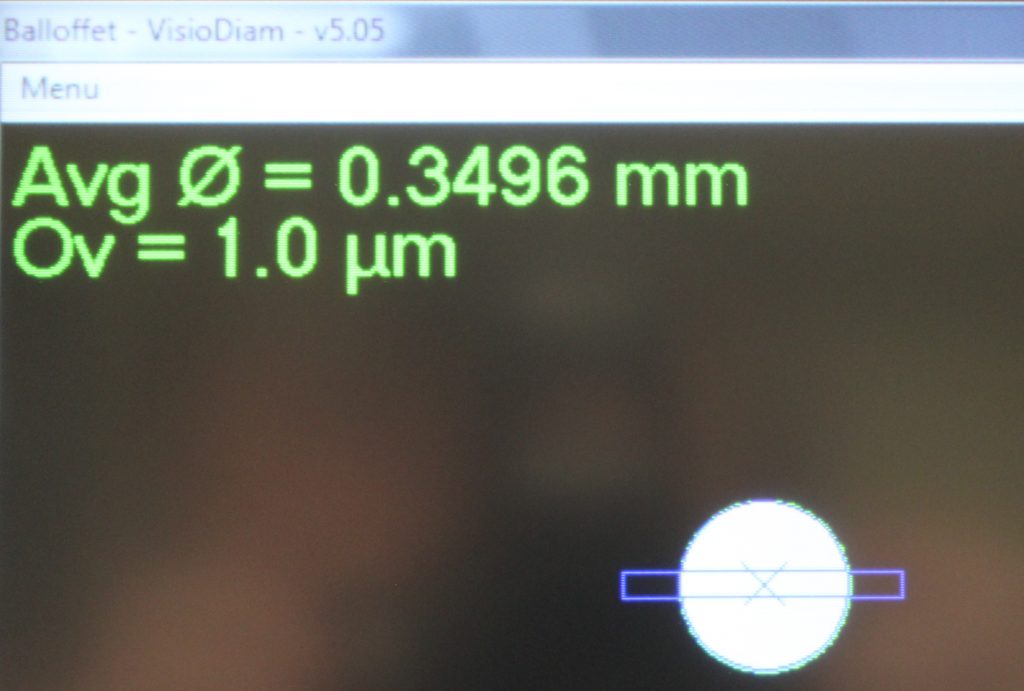

Reduce your dies and enamelling guides management costs!

- Diameter and ovality automatic control.

- Works for diamond and carbide tools

- Drawing dies and Enamelling guides